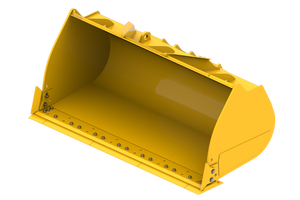

John Deere has announced the development of production series buckets for the 744K-II, 824K-II and 844K-III wheel loaders.

These buckets are designed with narrow spill guards, bushed static bucket pin joints, and optional wear plating. Profile side cutters also improve material retention, and make it easier for the bucket to be filled with loose material.

"In speaking with wheel loader users in the field, they drove home the fact they wanted a bucket option that would increase production and offer greater efficiency in material retention," said John Chesterman, product marketing manager of production class four-wheel drive loaders with John Deere Construction & Forestry. "We worked with our engineers to develop 30 configurations that improve loading and visibility; are easier and quicker to repair; and extend bucket life in all types of material."

The narrow spill guards of the redesigned buckets provide more visibility to the load, meaning the operator can easily see when the bucket is full. Over time, this reduces fuel consumption and the number of loads on the machine.

The static bucket pin joints reduce the need for welding and align boring for repair. In turn, this means less wear and tear, and a reduction in the amount of time and money spent on maintenance.

For more information on the production series buckets for the 744K-II, 824K-II and 844K-III wheel loaders, contact your local John Deere dealer or visit www.JohnDeere.com.